Please consult with us on any matters related to auxiliary welding materials.

KADOPITA

Manufacturing and sales of Kadopita is transferred from Nippon Steel Metal Products Co., Ltd. to us, and Kadopita is now one of our leading products with a good reputation. It is a grooved flat steel product that can be bent easily by hand. It is detailed designed to fit the corner R, which is different depending on the column manufacturer. Kadopita can also be used safely because it has obtained the certificate of construction technologies and performance. We can also achieve special machining for tapered columns with large inclination angles. Please contact us.

[Kadopita History]| 1993 | Nippon Steel Metal Products Co., Ltd., started development. |

| 1996 | Kadopita was successfully commercialized. Groove shape: V-shaped, Material: 9 mm x 16 mm flat steel A full-scale experiment was conducted at Nakagomi Laboratory of Shinshu University to confirm that the groove does not influence the breakage. However, Kadopita was difficult to be bent without a jig. |

| 1999 | Nippon Steel Metal Products Co., Ltd., transferred the Kadopita business to Sunouchi Corporation. We started manufacturing and sales of Kadopita. However, it was difficult to be bent and expensive to manufacture. We tackled the challenge of developing a new manufacturing method. |

| 2001 | We succeeded in the development of a new groove shape. Groove shape: concave shape, Material: 9 mm x 25 mm flat steel We started manufacturing and sales of Kadopita,with concave-shape grooves. Kadopita has become an epoch-making product that can be easily bent by hand. |

Welding experiment

Passed in robotic weldability!

Passed in the ultrasonic flaw detection test!

Passed in the macro test!

JIG G 3136

SN 490B Suitable chemical components for weldability!

Loading test

Breakage status

The column base material was broken. There is no effect on Kadopita.

The cumulative deformation magnification factor of n > 80 is achieved. Sufficient strength is ensured as a pillar.

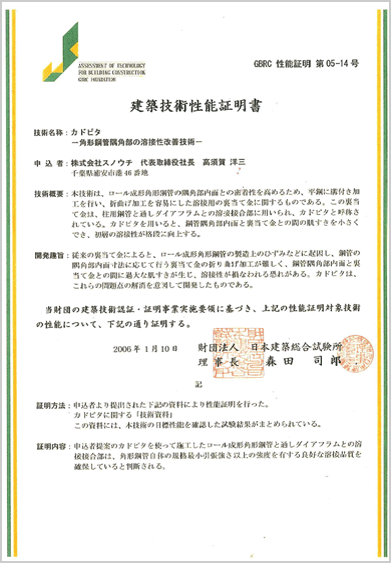

Certificate of construction technologies and performance

- The only certified product as a backing metal for columns

Composition of the ceramic tab

The Sunox-Ceramic Tab is designed not only to stop leakage of molten metal, but also to obtain sound welded starting and ending parts, and the components are adjusted to meet the following conditions.

(1) Welded metal parts should not be chemically and mechanically affected.

(2) Welded metal parts should be smoothly finished.

(3) The tab should have a melting point, thermal shock resistance, and heat-resistant cycle according to the amount of welding heat.

(4) Welding slag should not adhere to the ending bead of the welded metal.

We always carry out welding experiments to ensure the quality of raw materials when their source areas of origin are changed.

Welding test report of CP-40 with the raw material changed

Welding test report of CP-40 with the raw material changed

Please consult with us even for the shapes not included in our catalog.

We have been offering a variety of specially shaped ceramic tabs in response to customer requests. We can offer samples in your desired shaped tabs made of the same material as our ceramic tabs, even from one piece. So, you can use them in the actual welding procedure to check the usability. Some products are commercialized as general-purpose products based on requests from fabricators.

Used for the Japan National Stadium and other purposes, such as construction machinery, welding researches, and exclusive use for construction methods.

Ceramic backing material for reinforcing welded bar joint, Barpita®

Barpita was developed as a backing material for the reinforcing welded bar joint construction method by the Japan Reinforcing Bar Joints Institute (JRJI). This method is officially called a torch shielding welding method using ceramic backing materials with aluminum foil and windbreak hoods, which is one of the welding methods used for reinforcing bar joints. JRJI developed this method to improve further the convenience and workability of reinforcing welded bar joints and developing uniform technical standards and general construction methods in the situation where management complexity and reliability of construction quality are concerned with the recent diversification of the reinforcing welded bar joint methods.

Kadopita BF

◆ Developed together with Nippon Steel Metal Products

Processing for the welded parts of the column and the diaphragm is usually performed by reversing the cut and beveled column, cutting the inner bead, and welding the backing metal for the column. Kadopita BF was developed together with Nippon Steel Metal Products to eliminate the process of cutting the inner bead of the column and reversing the column for cutting the bead. Using this product reduces the time required for backing metal work by about 20% because the end part of Kadopita has a cutting part that fits the shape of the inner bead of the column, enabling work without cutting the inner bead. Kadopita BF obtained a certificate of construction technologies and performance from the General Building Research Corporation of Japan.

*The inner beads of some square steel pipes may need to be cut in some cases.

LL Hinge

◆ Developed together with Komaihaltec Inc.

LL Hinge was commercialized based on a request from Komaihaltec Inc. for production and a joint patent application to prevent incorrect installation. The mounting method is easy to understand, enabling smooth welding. You can use this product for splice plates of various weights and dimensions by increasing or decreasing the number of products to be mounted.

Example photograph